Developing aesthetically recycling methods and products in the Anthropocene - this is the interdisciplinary starting point with which the project ReFib - Recycling Fibroin as Textile Finishing is dedicated to the recycling of leftovers from silk production.

Worldwide, over 11 million tonnes of silk waste from production and used textiles are produced every year. As part of the bachelor's project described here, the BioLab of Burg Giebichenstein University of Art and Design Halle, in collaboration with Fibrothelium GmbH, investigated how the fabric remnants can be recycled and used for textile design. After the color sorting of tissue remnants, fibroins can be obtained by low-pollutant processes in solutions containing up to 10% fibroins. Organic forms such as sponges, films and granulates can be produced from this basic material. Only a small amount of the solution is sufficient for the refining process: One kilo of dissolved silk can be used to coat up to 100 kilos of wool.

From a design perspective, the focus is on which properties of the silk are retained in the recycling process: Can the optical sheen and the feel of the original silk be restored or transferred to other materials? Domestic wool in particular, whose quality is primarily scratchy, served here as a counterpart to silk. In various textile processes, the dissolved silk was applied to woolen yarn and fabric. Following the acid dyeing of protein fibers, series of experiments were conducted on the binding of dissolved silk to wool fibers.

The advantage here is that no additional crosslinkers are required for the wash-resistant binding of silk proteins to wool. The series of experiments show that, in addition to the fibroin, the dye of the silk was also bound to the wool fibre. At the same time, it could be validated that the material is perceived as softer and more skin-friendly after wool finishing with ReFib. Pasty fibroin was applied to textile surfaces using textile printing processes. In various application and curing processes, the fibroin could be bonded to wool fabrics in patterns. This method also offers potential as a mono-material finish on silk. Using design research methods, over a hundred samples have been created and documented. In cooperation with research- institutions and companies, we are investigating further scaleability. Under the research title silcularity, new strategies for a circular use of silks have thus emerged.

Technique: Dyeing, knitting

Material: 100% Wool + ReFib

Size: 10cm x 10cm

ReFib

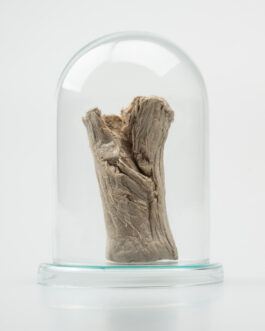

The development of the recycled fibroin (ReFib) took place in the BioLab of BURG. After color sorting of tissue remnants, water-soluble fibroins could be obtained in concentrations up to 10% wt. The liquid and pasty ReFib has been tested in further steps as textile finishing. In Cooperation with Fibrothelium GmbH the patented process called PureSilk® was used to dissolve larger quantities of silk residues.

from left to right:

Silkcocoon, silk residues, dissolved residues, dialysis, pasty ReFib

Technik: Refibfoam

Material: 100% Seide, ReFib.F.0.5

Größe: 10x5cm

Technik: Refibfilm

Material: 100% Seide, Fasern, ReFib.F.2.1

Größe: 9cm, Durchmesser

Lösemittel löst nur Seide, keine Cellulose

Material: Seidencellulosegewebe

Größe: 6x4cm

Dyeing

Following conventional liquor finishing processes such as dyeing, the water-soluble ReFib was attached to wool fibers. In various test series, the dye of the silk could be bonded to the wool fiber in addition to the fibroin. Comparability was achieved by means of counter tests. Different wool yarns, woven fabrics and knitted fabrics were grafted and compared.

Technique: liquor finishing

Material: 100% wool, ReFib

Size: 15cm

Technique: Counter test

Material: Wool, Cotton

Size: 10x10cm

Technik: Flottenveredelung, warm, sauer

Material: Wolle, Baumwolle, ReFib.09

Größe: 10x10cm

Technik: Flottenveredelung

neutral, kalt, 0.1%wt.

Material: Wolle, ReFib.10

Größe: 20x10cm

Technik: Flottenveredelung

sauer, warm, 0.1%wt.

Material: Wolle, ReFib.13

Größe: 20x10cm

Coating

Using textile printing and curing techniques, the ReFib could be bonded to wool fabrics in patterns.

This method also offers potential as a mono-material finish on silk.

Technique: Coating, curing

Material: 100% Wool, ReFib

Size: 100x80 cm

Technik: Coating

Lochblech, Transferpresse.

Material: Wolle, ReFib-Paste10

Größe: 15x15cm

Technik: Coating

Lochblech, Transferpresse.

Material: Wolle, ReFib-Paste10

Größe: 15x15cm

Technik: Coating

Spachteln, Transferpresse.

Material: Wolle/BW, ReFib-Paste13

Größe: 20x20cm

Technik: Gegentest

gebügelt

Material: Wolle/BW

Größe: 20x20cm

Thanks a lot for the support!

Prof. Bettina Göttke-Krogmann

Dr. Falko Matthes

Joachim Unterfrauner

Stephan Schmidt

Photographies: Kim Cordes

Assistance Photoshooting: Karl Schinkel, Lukas Zettl

Bachelor thesis in textile design of the BURG Giebichenstein University for Art and Design Halle on 01.02.2023, created by Kim Cordes.

Material and Machine donations

Barth & Könenkamp GmbH (Silk residues)

BioLab BURG (Laboratory)

Coastland GmbH & Co. KG (domestic wool)

DTNW gGmbH (research papers)

Fibrothelium GmbH (silk dissolving)

Gebrüder Mehler GmbH (merinowool)

ITM TU Dresden. (silk dissolving)

MLU Halle (dialysis tubes)

Nordwolle GmbH (domestic wool)

Rohleder GmbH (yarn)

Schleifenfänger Laura Hertel (silk residues)

Siebdruckwerkstatt BURG. (machines)

STFI e.V. (machines)

Zimmer + Rohde GmbH (silk residues)

Weberei BURG (yarns and looms)